- Home

- About Us

- Products

- Spherical Roller Bearing

- Turbocharger Bearings

- Cylindrical Roller Bearings

- N/NJ/NU/NUP Single Row Cylindrical Roller Bearings

- Cross Roller Bearings

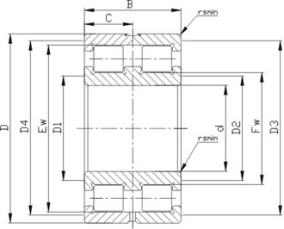

- Double Row Full Complement Cylindrical Roller Bearings

- NJ NCF-V Single Row Cylindrical Roller Bearings

- NN Double Row Cylindrical Roller Bearings

- NNC-V NNF-V Double Row Cylindrical Roller Bearings

- RSL single row full complement cylindrical roller bearings

- Single Row Full Complement Cylindrical Roller Bearings

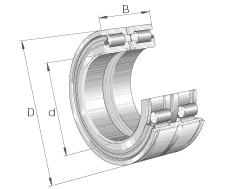

- SL Double Row Full Complement Cylindrical Roller Bearings

- Pillow Blocks

- Ball Bearing Inserts NA2 and HC2

- CSB Series

- NAFLU2 Series

- NAFU2 Series

- SB2, SB2G, SA2, SA2G Series

- SBFD2 Series

- SBLP2 ,SALP2 Series

- SBPF2,SBPFT2 Series

- SBPFL2, SAPLF2 Series

- SBPFTD2, SAPFTD2 Series

- SBPP2, SAPP2 Series

- SC Series

- SER2 Series

- UC2 Set Screw Type ,RB2 Set Screw Type

- UC3 Series

- UCC2 Series

- UCF2 Series

- UCFC2, NAFC2 Series

- UCFK2 Series

- UCHA2 Series

- UCP2 , NAP2 Series

- UCPA2 Series

- UCPH2 Series

- UCPK2 Series

- UCT3 Series

- UCX Series

- UK2 Series

- Taper Roller Bearings

- Needle Roller Bearings

- Axial Cylindrical Roller and Cage Assemblies

- Axial Cylindrical Roller and Cage Assemblies

- Axial Needle Roller and Cage Assemblies

- Axial Needle Roller Bearing With Centring Spigot On the Bearing Washer

- Drawn Cup Full Complement Needle Roller Bearings

- Drawn Cup Needle Roller Bearings - HK BK type

- Drawn Cup Roller Clutches Clutch And Bearing Assemblies

- Heavy Duty Full Complement Needle Roller Bearings

- Heavy Duty Needle Roller Bearings With Inner Ring

- Heavy Duty Needle Roller Bearings Without Inner Ring

- Heavy Duty Needle Roller Bearings Without Ribs

- Long Cylindrical Roller and Cage Assemblies

- Radial Needle Roller and Cage Assemblies - K type

- Radial Needle Roller and Cage Assemblies - KBK type

- Radial Needle Roller and Cage Assemblies - KZK type

- Sealed Drawn Cup Needle Roller Bearings

- Sealed Heavy Duty Needle Roller Bearing With or Without Inner Ring

- Sealed Yoke Type Track Rollers Without Axial Guidance

- Yoke Type Track Rollers Without Axial Guidance

- IR LR Inner Ring

- CF Series Needle Roller Bearing

- MR/HJ/SJ/NCS Series Needle Roller Bearing

- FC/FCB Series Needle Roller Bearing

- RC/RCB Needle Roller Bearing

- SCE Series Inch Needle Roller Bearing

- NTB Thrust Needle Roller Bearing

- NATR/NATV…PP Needle Roller Bearing

- CRY...V/CRY...VUU Yoke Type Track Rollers Bearing

- RNAO Series Needle Roller Bearing

- Deep Groove Ball Bearings

- Double Row Deep Groove Ball Bearings

- Heavy Load Deep Groove Ball Bearings

- Miniature Ball Bearings

- Miniature Ball Bearings With Flange

- Single Row Deep Groove Ball Bearings Close Type

- Single Row Deep Groove Ball Bearings Open Type

- Single Row Deep Groove Ball Bearings With Snap Ring

- Miniature Metric Bearings

- Miniature Inch Bearings

- Miniature Extended Bearings

- Metric Miniature Flanged Ball Bearings

- Inch Miniature Flanged Ball Bearings

- Miniature Flanged Extended Bearings

- Angular Contact Ball Bearings

- Ceramic Precision Spindle Bearings - HC, HCS types

- Ceramic Precision Spindle Bearings - HCB types

- Chrome Steel Precision Spindle Bearings - B types

- Double Row Angular contact ball bearing - open type

- Double Row Angular contact ball bearing - Seals type 2RS

- Double Row Angular contact ball bearing - shields type ZZ

- Four point contact ball bearings

- Matched Angular Contact Ball Bearings

- Single Row Angular Contact Ball Bearings

- Spherical Plain Bearings

- Thrust Cylindrical roller bearings

- Inserts

- Thrust Ball Bearings

- Self-Aligning Ball Bearings

- Slewing Ring Bearings

- Double Row Different Diameter Ball Slewing Bearings - 02 Seires

- Single Row 4 Point Contact Ball Slewing Bearing - 01 Series

- Single Row 4 Point Contact Ball Slewing Bearing - HS Series

- Single Row 4 Point Contact Ball Slewing Bearing - Q Series

- Single Row Crossed Roller Slewing Bearings - 11 Series

- Single Row Crossed Roller Slewing Bearings - HJ Series

- Three-row cylindrical rollers slewing ring bearings - 13 Series

- Three Row Cylindrical Rollers Slewing Bearings - SW/SN Series

- XRA Cross Roller Bearing

- XRB Cross Roller Bearing

- XRBC Cross Roller Bearing

- XRBH Cross Roller Bearing

- XRC Cross Roller Bearing

- XRE Cross Roller Bearing

- XRSU Cross Roller Bearing

- Combined Bearings

- Standard Combined Bearings

- Adjustable Combined Bearings

- Adjustable Combined Bearings for Heavy Load Industry

- Adjustable Combined Bearings for Steel Industry

- Adjustable Combined Bearings with Eccentric Pin

- Adjustable Combined Bearings with Plastic Axial Roller

- Adjustable Combined Bearings with Screw

- High Speed Combined Bearings

- JUMBO Combined Bearings

- Cam Followers

- Track Roller Bearings

- Cam Rollers

- Chain Pulley - Cylindrical Roller Type

- Chain Pulley - Double Row Angular Contact Ball Bearing Type

- Chain Pulley - Single Row Deep Groove Ball Bearing Type

- Conveyor Track Rollers

- LFR Bearings

- LR Bearings

- Mast Rollers - Double Row Angular Contact Ball Bearing Type

- Mast Rollers - Single Row Deep Groove Ball Bearing Type With Crowned Outer Ring

- Yoke Type Track Rollers - NATRNATV Series

- Yoke Type Track Rollers - NKIA Series

- Yoke Type Track Rollers - NUTR Series

- Yoke Type Track Rollers - PWTR Series

- Yoke Type Track Rollers - RSTO Series

- Yoke Type Track Rollers - RSU Series

- Linear Bearings

- KBA - Shaft Supporting Housing

- KBA-AJ - Shaft Supporting Housing

- KBA-L - Shaft Supporting Housing

- KBA-S - Shaft Supporting Housing

- KBB - Shaft Supporting Housing

- KBB-AJ - Shaft Supporting Housing

- KBB-OP - Shaft Supporting Housing

- KBE - Shaft Supporting Housing

- KBSB - Shaft Supporting Housing

- KBSB-AJ - Shaft Supporting Housing

- LME…LUU Linear Motion Bearings

- LME…UU UUAJ UUOP Linear Motion Bearings

- LM…LUU Linear Motion Bearings

- LM…UU UUAJ UUOP Linear Motion Bearings

- PA - Shaft Supporting Housing

- S Series Linear Shaft

- SHF - Shaft Supporting Housing

- SHF-B - Shaft Supporting Housing

- SI Series Linear Shaft

- SK - Shaft Supporting Housing

- SKB Series Linear Motion Bearings

- SKB-OP Series Linear Motion Bearings

- SKW - Shaft Supporting Housing

- SLM Series Linear Motion Bearings

- SLM-OP Series Linear Motion Bearings

- SMA - Shaft Supporting Housing

- SMA-AJ - Shaft Supporting Housing

- SMA-L - Shaft Supporting Housing

- SME - Shaft Supporting Housing

- SME-L - Shaft Supporting Housing

- SP Series Linear Shaft

- SSW Series Linear Motion Bearings

- SSW-OP Series Linear Motion Bearings

- SWA - Shaft Supporting Housing

- SWA-L - Shaft Supporting Housing

- SWB - Shaft Supporting Housing

- SWB-L - Shaft Supporting Housing

- SWB-L-OP - Shaft Supporting Housing

- SWB-OP - Shaft Supporting Housing

- SWD - Shaft Supporting Housing

- SWD-L - Shaft Supporting Housing

- TBR - Shaft Supporting Housing

- Agricultural Bearings

- Automotive Bearings

- Rolling Mill Bearings

- Water Pump Bearings

- Double-row Ball Water Pump Bearings - Angular Contact

- Double-row Ball Water Pump Bearings - WB 1938 Series

- Double-row Ball Water Pump Bearings - WB1224 Series

- Double-row Ball Water Pump Bearings - WB1630 Series

- Double-row Ball Water Pump Bearings - WB1940 Seires

- Double-row Ball Water Pump Bearings - WD1226 Seires

- Double-row ball water pump bearings - WIB Series

- Single Row Ball and Roller Water Pump Bearings - WIR Series

- Single Row Ball and Roller Water Pump Bearings - WR Series

- WHY CHOOSE US

- Industry

- Service

- News

- Contact Us

English